NEWS

NINGBO JIANGBEI JUNYUAN ELECTROMECHANICAL TECHNOLOGY CO., LTD is among the first few Hi-tech enterprises which focus on designing and manufacturing transmission system for electric vehicles. The company was founded in 2002. our company with experience in designing、controlling and manufacturing of motors for electric vehicles, ANGYANG has manufactured several types of motor products with self-owned Intellectual Property Rights. Its business scope covers electric motors and control system for electric wheelchair, electric bicycle, electric motorcycle, electric scooter, special electric transporter and mini electric car.

The new national standard boosts lithium-ion bicycles, and the analysis of China's electric bicycle industry supply and demand structure and market prospect trend in 2019 [Figure]

time:

2020-12-24 09:08

Source:

According to national standards, electric bicycles refer to the use of storage batteries as auxiliary energy sources.

1. Definition of electric bicycle products

According to national standards, electric bicycles refer to the use of storage batteries as auxiliary energy sources. On the basis of ordinary bicycles, they are equipped with motor, controller, storage batteries, handlebars and other operating components and display instrument systems. The maximum speed is not higher than 25km/h. Mechatronics personal transportation with a vehicle mass of no more than 55kg.

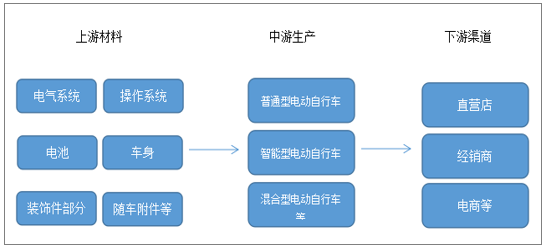

The composition of electric bicycles

Part | Overview |

Frame | The frame is the main part of the electric bicycle. It is the main body of the installation and connection of other parts of the whole vehicle, and bears all loads. It is related to the personal safety of the rider during the riding process. |

Motor | The motor is a component that converts electrical energy into mechanical energy and drives the wheels of an electric bicycle to rotate. The types of motors can be divided into AC motors, DC motors, etc. according to their current form, disc motors, hub motors, etc. according to the structure, and switched reluctance motors and rare earth permanent magnet motors according to the method of magnetic field generation Wait. At this stage, the most commonly used motors on electric bicycles are mainly rare earth permanent magnet brushless gearless hub DC motors, rare earth permanent magnet brushless geared hub DC motors, and a small number of other types of motors. |

Battery | Batteries are on-board energy storage devices that provide electric energy for electric bicycles. The batteries for electric bicycles are mainly divided into lead-acid batteries and lithium-ion batteries. |

Controller | The controller is the heart of the electric bicycle electrical system and the core component of the electric bicycle energy management and various signal processing. It has the function of undervoltage or overcurrent protection. The intelligent controller also has a variety of riding modes and a self-checking function for the electrical components of the vehicle. |

Charger | The charger is an electrical device that replenishes energy to the battery. It converts alternating current into direct current and controls its voltage and current to charge the battery for storage. |

Source: Zhiyan Consulting

Electric bicycles have great environmental advantages and are also one of the most convenient short-distance commuting tools. Facing the fact of global warming and the relative shortage of oil resources in my country, the development of the electric bicycle industry is in line with my country's national conditions. At the same time, the industry is also an important civilian production industry in my country and has broad development prospects. To this end, the state has proposed a series of industrial policies to support the development of the industry, and at the same time promulgated relevant regulations and standards to regulate the electric bicycle industry.

From the upstream of the industry, motors, batteries, and controllers are the core raw materials. At present, the production technology of upstream enterprises in this part has become mature, and there have been many well-known manufacturers of batteries, motors, and controllers, with a certain scale and industry influence, and the standardization of products is extremely high. Especially in the battery sector, a duopoly pattern of lead-acid batteries has been formed: Tianneng Power and Chaowei Power have accounted for more than 80% of the industry for several consecutive years.

Electric bicycle industry chain

Source: Zhiyan Consulting

At the same time, industry production has extremely obvious scale benefits. With the expansion of the production scale of major enterprises in the industry, the automation level of industry production has increased significantly, the proportion of manufacturing expenses has continued to fall, and the proportion of raw material costs has increased. From the perspective of production costs, among the current production costs of the electric bicycle industry, the raw material costs of major companies have accounted for more than 90%, and some larger companies can reach about 95%.

Of course, in the process of realizing sales, enterprises still need to promote marketing, channel rebates, etc. With the fierce market competition, the marketing costs of the industry are also rising. But generally speaking, the cost of raw materials is still the most important cost, which can generally reach more than 60% of the entire production cost, accounting for about 50% of the product price. The gross profit rate of the industry is generally low, and fluctuations in cost prices, especially the prices of raw materials, have a relatively important impact on industry product prices and corporate profitability.

2. Development of the electric bicycle industry

With the continuous development of urbanization, the number of cars in my country has been increasing year by year, and the problem of urban traffic congestion has become more and more serious. Bicycles are gradually eliminated in competition with electric vehicles and motorcycles. Although motorcycles have many advantages over electric vehicles, due to the continuous strengthening of motor vehicle control policies in various cities and the lack of portability, they are gradually being used by electric bicycles. Replaced.

In general, China is the world's largest producer and consumer of electric bicycles. At present, electric bicycles have become an important travel tool for many office workers, couriers, and takeaways. At the same time, the bicycle-sharing industry introduced electric bicycles, the market demand expanded rapidly, and the industry output rebounded significantly. In addition, the country has been advocating green travel, which has promoted the development of electric bicycles.

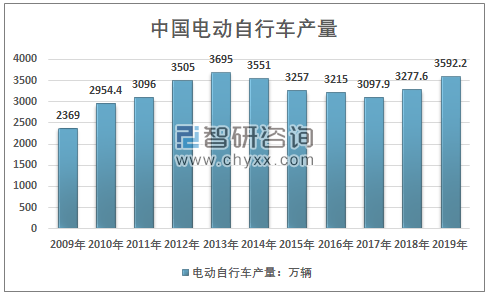

At present, there are two publishing agencies for the data of electric bicycle production, one is the National Bureau of Statistics (statistics of enterprises above designated size), and the other is the statistics of bicycle associations. The statistics of the National Bureau of Statistics are mainly for enterprises above designated size, with relatively small output. According to statistics from the China Bicycle Association, China's electric bicycle output reached 35.922 million in 2019.

2009-2019 China Electric Bicycle Production Trend

Source: China Bicycle Association, Zhiyan Consulting

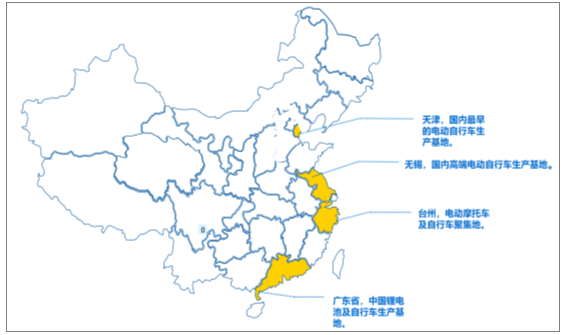

From the perspective of production area, my country's electric bicycle industry has formed an extremely obvious aggregation effect. The main traditional production areas of electric vehicles in my country are Tianjin in the north, Wuxi, Taizhou and Guangdong in the south. Among them, Tianjin is the earliest electric bicycle production base in China. It started with bicycles and gathered a large number of well-known companies such as Emma and Xiaodao; Wuxi is the headquarters of two listed companies in the electric bicycle industry, Xinri and Yadi; Taizhou is Relying on the location and manufacturing advantages, as well as the advantages of plastic film, it has become the largest mold supply base for electric vehicles in China, gathering a number of well-known enterprises such as Lima and Lvjia; Guangdong famous brands such as Tailing.

Distribution of electric bicycle production bases in China

Source: Zhiyan Consulting

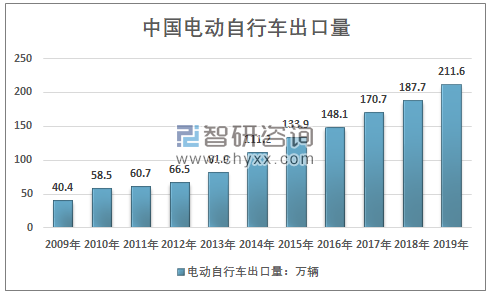

China is the world’s largest producer, exporter and consumer of electric bicycles. In recent years, China’s export volume of electric bicycles has maintained a steady growth trend. In 2009, China’s export volume of electric bicycles reached 404,000. In 2019, China’s electric bicycle production and exports reached 2.116 million vehicles were sold.

2009-2019 China's export volume trend of electric bicycles

Source: China Customs, Zhiyan Consulting

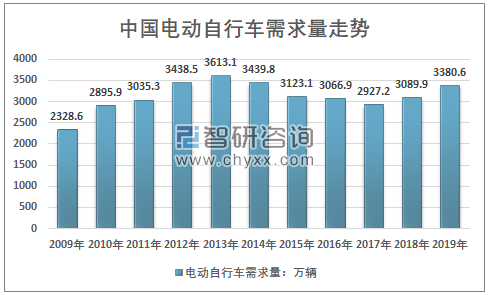

The "Analysis Report on the Market Competition and Business Model of China's Electric Bicycle Manufacturing Industry for 2020-2026" released by Zhiyan Consulting pointed out that from the perspective of domestic market demand, the domestic demand for electric bicycles has rebounded significantly in the past two years. In 2017, the demand for China's electric bicycle industry was only 29.272 million. In 2019, it has rebounded to 33.806 million.

2009-2019 China's electric bicycle industry supply and demand balance

Source: China Bicycle Association, Zhiyan Consulting

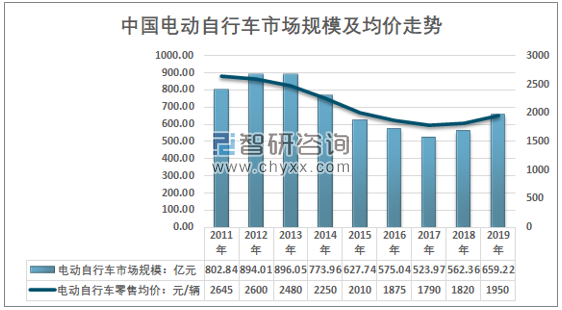

In 2019, the average retail price of my country's electric bicycle industry is about 1950 yuan/unit, and the sales volume is about 33.806 million units. The retail market size of the domestic electric bicycle industry is about 65.922 billion yuan.

2011-2019 China's e-bike industry retail average price and scale

Source: Zhiyan Consulting

As the technology of electric bicycles is gradually becoming mature and practical, in addition to energy saving, economy and environmental protection, electric bicycles also have the labor-saving and time-saving features of motor vehicles, which are in line with the consumption characteristics and needs of today's Chinese consumers. After just a few years of development It has a huge consumer base. So far, China has become the world's largest producer and consumer of electric bicycles, with annual output and consumption accounting for more than 90% of the world's total output and consumption. At present, my country has formed an electric bicycle industry cluster, and Tianjin, Jiangsu and Zhejiang have become the main production areas of electric bicycles. The electric bicycle industry has no obvious periodic characteristics. The consumer demand for electric bicycles is inseparable from the continuous economic growth, the improvement of people’s living and income levels, and the pursuit of quality of life. Therefore, the cyclical characteristics of the electric bicycle industry are basically consistent with the overall cyclicality of the economy. Will continue to maintain a high degree of prosperity.

3. Industry product structure analysis

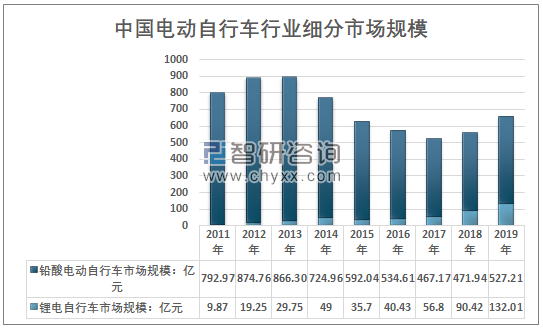

The classification of electric bicycles mainly depends on their battery types. The batteries used in electric bicycles can be divided into lead-acid batteries and power batteries. In May 2018, the mandatory national standard "Electric Bicycle Safety Technical Specifications" (GB17761-2018) was revised by the Ministry of Industry and Information Technology. Since its formal implementation on April 15, 2019, with the implementation of the new national standard for electric bicycles, lead-acid batteries have been unable to meet the upper limit of 55Kg for the weight of electric bicycles, so the proportion of lithium batteries for electric bicycles has increased rapidly.

In 2019, the consumption of electric bicycles in my country was 33.806 million, among which, the sales of lithium bicycles were about 6.14 million, accounting for 18.16%, and the sales of non-lithium bicycles were 27.66 million, accounting for 81.84%.

2011-2019 my country's electric bicycle sales structure

Source: Zhiyan Consulting

The proportion of lithium batteries used in electric bicycle batteries is also in the process of increasing. Professional consumer lithium battery/electric vehicle lithium battery companies such as ATL, Ningde Times, Xingheng Power and Yiwei Lithium Energy have also deployed in this market. There are also some professional companies such as Bafang shares that specialize in providing motor manufacturing for electric treadmills. At present, the upstream of the electric bicycle industry has formed a standardized and modular supply capacity, which has greatly promoted the development of the electric bicycle industry.

However, in general, although lithium batteries have the advantages of small size, long life, and large unit capacity compared with lead batteries, their cost is high. Lead batteries are easily accepted by consumers due to their low manufacturing costs. Therefore, electric bicycles currently on the market The batteries used are mainly lead storage batteries. Moreover, the main demand-side shared travel companies mainly use brand owners to release shared electric bicycles. Due to the large demand for release, in order to control costs, brand owners mainly use low-cost non-lithium battery electric bicycles. In my country's electric bicycle industry in 2019, the lithium battery market has reached 13.201 billion yuan.

2011-2019 my country's electric bicycle market segment trend

Source: Zhiyan Consulting

4. Industry technology development prospects and trends

In addition to energy-saving, economical, and environmentally friendly, electric bicycles also have the labor-saving and time-saving features of motor vehicles, which are in line with the consumption characteristics and needs of today's Chinese consumers. As electric bicycle technology gradually becomes mature and practical, it has a huge consumer group after just a few years of development. So far, China has become the world's largest producer and consumer of electric bicycles, with annual output and consumption accounting for more than 90% of the world's total output and consumption.

From the perspective of market demand, my country is already the world's largest consumer of electric bicycles. With the continuous growth of China's economy, the continuous improvement of consumption levels, the continuous updating of people's consumption concepts, the stable urbanization process, and the promotion of new energy and energy saving and emission reduction policies, market demand will continue to maintain steady growth.

At present, the electric bicycle industry has entered a mature period, the market is relatively standardized, and the era of relying on homogeneous products to gain market share is gone. The internal reform of the industry is evolving in depth, and the brand development road with product innovation as the core has become The main path.

The promulgation of the "New National Standard" in 2018 is the starting point for the supply-side structural reform of the electric bicycle industry and the increase in the added value of the bicycle industry. The implementation of this standard further accelerates market differentiation, making the industry present a “horse Too effective". With the improvement of electric bicycle technology and the enhancement of consumer brand awareness, the market capacity of first-line brand electric bicycle manufacturers will continue to expand, market share will steadily increase, and brand influence will continue to increase. Industry concentration will be further enhanced, and product value will also increase.

From the perspective of industry technology development trends, China is in a wave of consumption upgrades. The new crown pneumonia epidemic has caused a greater impact on optional consumption, but the long-term positive trend remains unchanged. In the transportation field, electric bicycles have quickly replaced traditional bicycles as the mainstream mode of short-distance travel due to their environmentally friendly and convenient characteristics. As the electric bicycle market becomes saturated, consumers have shifted from early product demand to quality, function, personality, and As experience demands change, conventional electric bicycles can no longer meet the market's requirements for new products.

In the future, electric bicycle manufacturers will focus on solving the pain points of consumers, abandon traditional low-end models with poor experience, and vigorously develop a new generation of high-end models represented by intelligence, high-end and personalization, and enhance product competitiveness and brand image. At present, several large domestic bicycle-sharing companies are also looking for new breakthroughs in lithium-ion electric bicycles, constantly developing new smart products, and electric vehicles have also entered the era of intelligence, beginning to develop in the direction of interconnection, intelligence, and interaction.

The application of Internet of Things technology and the development of new products and technologies have also allowed electric bicycles to incorporate more new elements, such as GPS, GPRS, MEMS, BLE, etc. GPS can locate vehicles, GPRS can realize vehicle networking, MEMS can detect the abnormal state of vehicles, and BLE can connect with smart phones. With the new elements of the Internet of Things, it can provide users with more personalized products.

In the future, the product development and innovation of electric bicycles should adhere to the consumer-centric approach, with the goal of improving user experience, and constantly develop intelligent products to meet the high-end market demand. In the next step, the industry should increase efforts to promote product intelligence. Taking advantage of the big data technology and the Internet of Things technology, product quality, user behavior analysis, quality management, public opinion analysis, after-sales service analysis, etc. will gradually be reflected in electric bicycle products and services. At the same time, the construction of "smart workshops" should be accelerated, and technology should be used to empower the production process to improve production efficiency and the reliability and consistency of product quality.

News

Lime, an electric scooter rental company, exits 12 markets in the U.S. and overseas

On January 10th, according to foreign media reports, Lime, an electric scooter rental start-up company, will lay off about 14% of its employees and withdraw from 12 markets in the United States and overseas.

Electric scooters have also begun the pace of global expansion

Like all shared travel services, regulation is becoming a big issue for electric scooter companies.

Electric treadmills are positioned as sports and health consumer goods. Compared with pure electric bicycles, they are not just a traditional means of transportation.